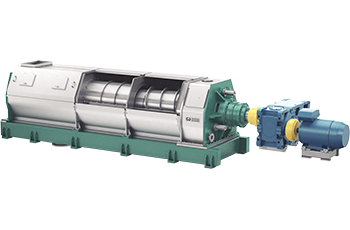

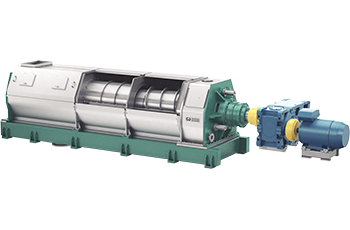

Screw press

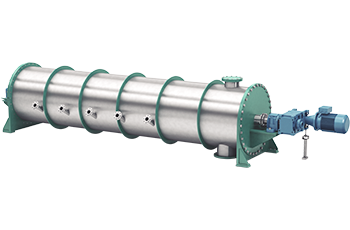

Dewatering is made to thicken the pulp consistency from as low as 3% and up to 35%. A high consistency pulp entering the heating zone will ensure a low steam consumption, and a better dispersion result.

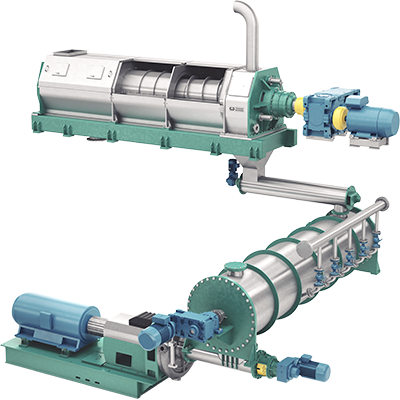

The CDS is the only non-pressurized system. This principle allows for a more compact design: a conveyor can be used to replace both the plug screw and the shredder, and there is no need for pressure vessels or sealings for HC discharge. The non-pressurized concept gives a low steam consumption, and the design also allows for existing dewatering equipment to be used. Retention time is 20-30 seconds at a temperature of up to 95°C (203°F).

The system is further described below – with treatment steps for dewatering, heating and dispersing.

Dewatering is made to thicken the pulp consistency from as low as 3% and up to 35%. A high consistency pulp entering the heating zone will ensure a low steam consumption, and a better dispersion result.

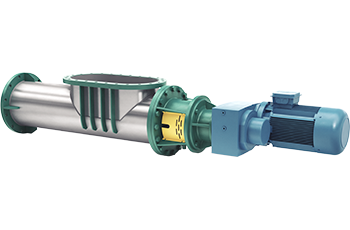

The Compact Dispersing System is a non-pressurized system and therefore a conveyor can be used to replace both the plug screw and the shredder. This gives a more compact solution for feeding to the pre-heater.

The pulp is heated to an even temperature of up to 95°C, depending on raw material. Strength properties are weakened, and an improved dispersing result can be achieved.

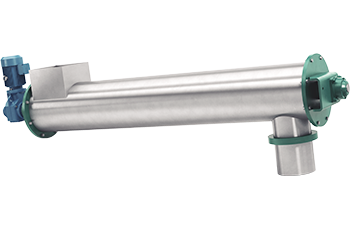

The infeeder feeds the pulp from the pre-heater to the disperser. The infeed zone of the disperser has patented features that decreases risk of blocking, and contributes to a low energy consumption.

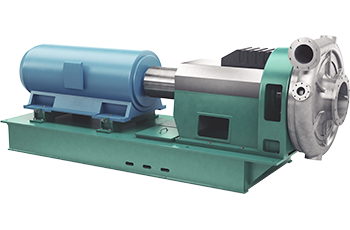

The fibers pass through a narrow gap between rotating discs, where any impurities are disintegrated to an invisible size. The devil-tooth pattern of the discs is optimized for each pulp mixture in order to achieve a gentle treatment of the fibers. Adjustment of the disc gap can be done on-line with an accuracy of 0,01 mm.

Test your material in our pilot plant and analyze machine performance in our lab!

Download InfoCustomized designs for your unique application.

Full service on site with your machine delivery.

We have offices in Sweden, Canada, Germany, China, and agents all over the world.

Let us visit your plant and help you improve performance!

Download Info

Are you in need of technical support or wear parts for your machine? Interested in a visit from our staff or a project quotation? Please contact one of our local offices around the world!

Johan Göth

Niklas Tunell

Christian Stiller

Åsa Billfeldt

Gith Cedulf

Stefan Virtanen

Tomas Anarp

Kevin Klassen

Frank Jiang

Kent Xu

Tony Lu

Cellwood Machinery